Manufacturing: digitalize and elevate your production

Manufacturing spans planning, execution and performance monitoring. In today’s demanding environment, operations must gain agility, precision and full transparency.

- Agile production

- Reliable traceability

Key challenges in modern manufacturing

Optimizing resources

Using labor, equipment, materials and energy as efficiently as possible is essential to maintaining quality and improving profitability. Industrial performance ...

Anticipating disruptions

Manufacturers must respond quickly to supply shortages, volatile demand and technical incidents. With SAP solutions such as PP/DS and Digital Manufacturing, you...

End-to-end traceability

From raw materials to finished goods, every step must be traceable to guarantee quality, regulatory compliance and transparency. SAP QM, LIMS and MES systems he...

Environmental transition and compliance

Industrial organizations must reduce their carbon footprint, meet sustainability targets and comply with evolving regulations. SAP supports energy optimization,...

Optimizing resources

Using labor, equipment, materials and energy as efficiently as possible is essential to maintaining quality and improving profitability. Industrial performance depends on the ability to plan accurately, monitor real-time KPIs and manage maintenance proactively to avoid downtime and ensure consistent output.

Anticipating disruptions

Manufacturers must respond quickly to supply shortages, volatile demand and technical incidents. With SAP solutions such as PP/DS and Digital Manufacturing, you can simulate scenarios, adjust scheduling in real time and build a more resilient supply chain. The goal: limit the impact of unexpected events and secure overall performance.

End-to-end traceability

From raw materials to finished goods, every step must be traceable to guarantee quality, regulatory compliance and transparency. SAP QM, LIMS and MES systems help track batches, operations and inspections at each stage. Integrated digital traceability reduces compliance risks, simplifies audits and strengthens trust with customers and partners.

Environmental transition and compliance

Industrial organizations must reduce their carbon footprint, meet sustainability targets and comply with evolving regulations. SAP supports energy optimization, waste reduction and real-time monitoring of environmental indicators, helping manufacturers operate more sustainably while meeting local and international standards.

Our approach to manufacturing excellence

A deep understanding of shop-floor realities

Our knowledge of these tools allows us to design robust, coherent architectures aligned with industrial objectives.

Strong capability to connect ERP with production systems

Real value comes from seamlessly linking the ERP with shop-floor technologies such as MES, LIMS or IoT.

This ensures digital continuity across strategic, tactical and operational levels: smoother data flows, faster responsiveness and reinforced traceability.

A project approach adapted to industrial environments

Our methodology blends SAP Activate principles with agile, shop-floor-oriented practices:

- Short iterations and incremental deliveries

- Strong involvement of business teams from day one

- Frequent testing and structured feedback loops

- Design validation through cross-functional reviews

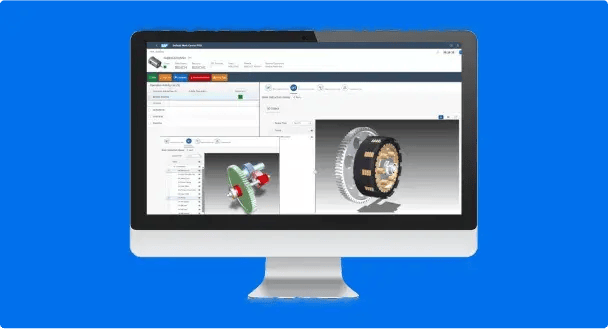

SAP Digital Manufacturing Cloud (DMC)

Real-time shop-floor execution, standardized KPIs, POD Designer and extended collaboration across production teams.

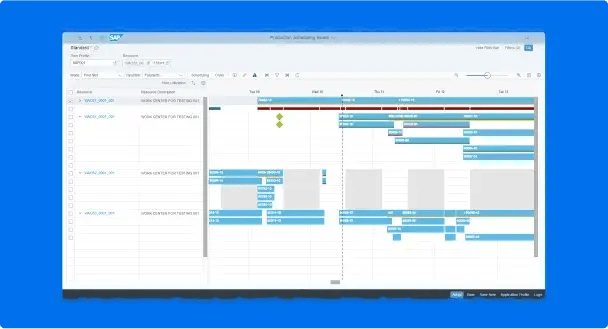

SAP PP-DS

Advanced planning and scheduling integrated with S/4HANA: capacity-aware planning, optimized sequencing and reduced downtime.

SAP MII/SAP ME

Middleware and MES capabilities connecting ERP to the shop floor: equipment integration, automation interfaces, top-floor/shop-floor synchronization and end-to-end traceability.

Optimize your production operations with our SAP experts

- Real-time control

- Connected data