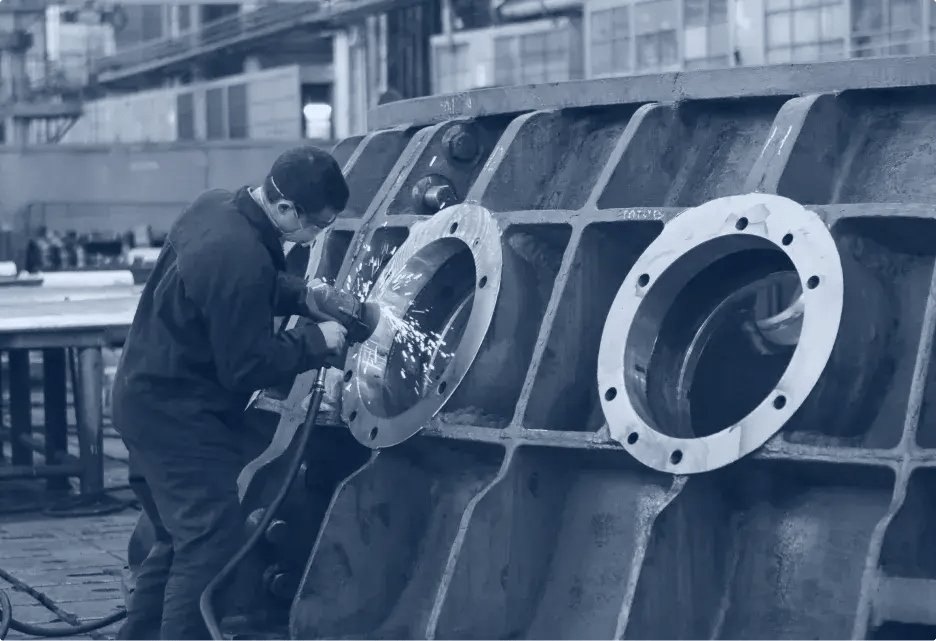

Manufacturing: modernize and streamline your operations

The manufacturing sector is undergoing major transformation: Industry 4.0, cost pressure, environmental expectations and workforce constraints are reshaping the way factories operate. To stay competitive, manufacturers must modernize their systems, strengthen agility and secure operational excellence across their plants.

- Operational digitalization

- Real-time performance management

Key challenges in the manufacturing industry

Strengthening supply chain resilience

Anticipate disruptions, diversify sourcing and optimize inventory to protect operations in an uncertain environment.

Manufacturers need greater visibility an...

Addressing the skills shortage

Sustain industrial performance despite the difficulty of attracting and retaining qualified technical profiles.

An aging workforce and increased competition ...

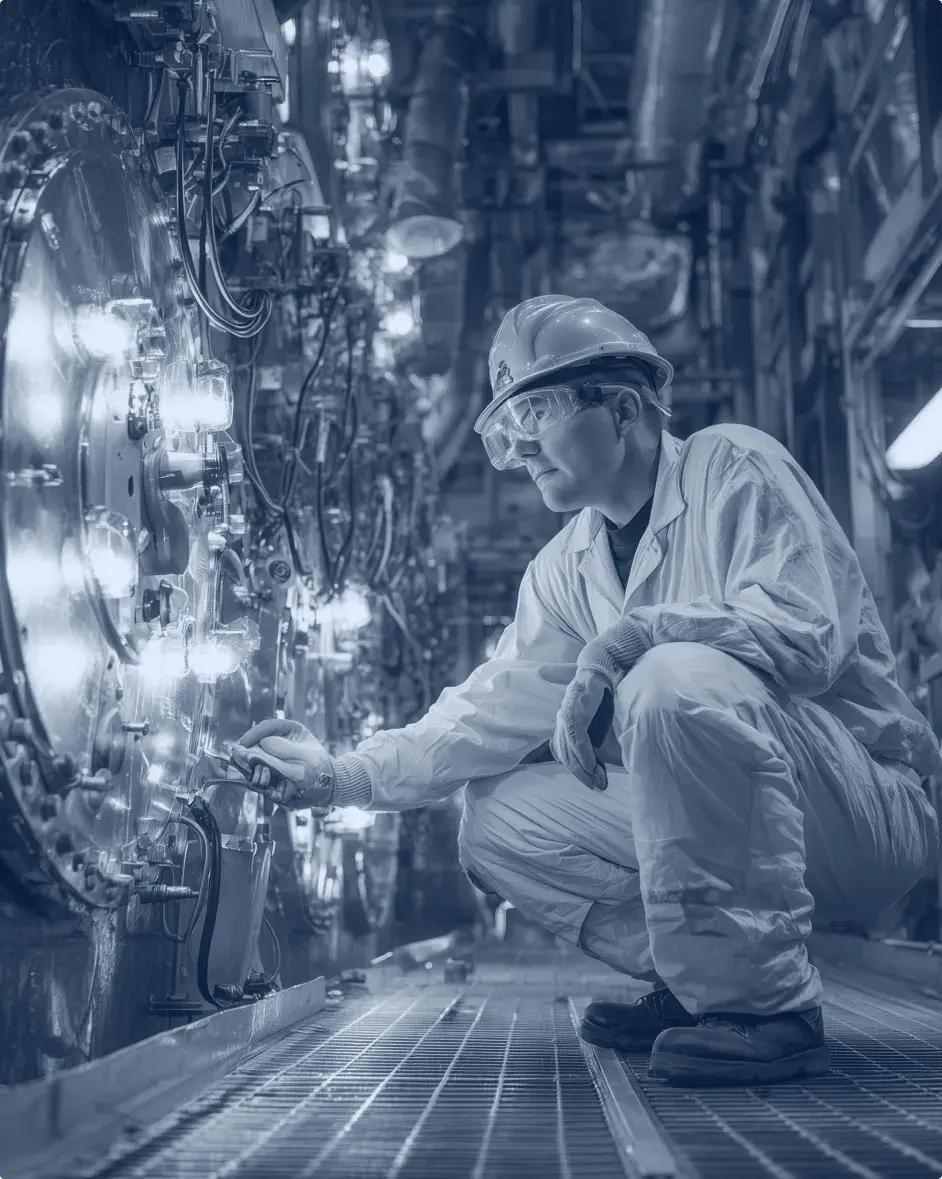

Securing industrial systems

Reinforce cybersecurity as equipment becomes increasingly connected.

As machines, sensors and production lines become more networked, cyber risks rise sharpl...

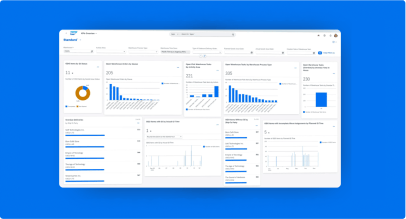

Driving real-time performance management

Rely on accessible, accurate data to adjust priorities and decisions quickly.

Real-time visibility - from shop floor to headquarters—enables faster decision-...

Boosting productivity through digitalization

Digital workflows, connected maintenance and automated logistics help improve throughput, reduce variability and optimize resource use across the factory.

Strengthening supply chain resilience

Anticipate disruptions, diversify sourcing and optimize inventory to protect operations in an uncertain environment.

Manufacturers need greater visibility and agility to manage supply risks, secure critical materials and maintain production continuity despite global volatility.

Addressing the skills shortage

Sustain industrial performance despite the difficulty of attracting and retaining qualified technical profiles.

An aging workforce and increased competition for skilled labor put pressure on daily operations. Digital tools, automation and Industry 4.0 practices are now essential to maintain productivity and transfer know-how.

Securing industrial systems

Reinforce cybersecurity as equipment becomes increasingly connected.

As machines, sensors and production lines become more networked, cyber risks rise sharply. Protecting production systems and ensuring data integrity is now a core requirement for operational stability.

Driving real-time performance management

Rely on accessible, accurate data to adjust priorities and decisions quickly.

Real-time visibility - from shop floor to headquarters—enables faster decision-making, waste - reduction and better responsiveness when disruptions occur.

Our expertise in the manufacturing industry

We combine strong SAP expertise with real on-the-ground industrial experience to support transformation projects across production, maintenance, quality and logistics. Our teams understand the realities of plant operations and design solutions that deliver measurable operational impact.

Proven expertise across SAP’s industrial modules

Our consultants bring deep knowledge of SAP’s manufacturing footprint (PM, MM, QM, EWM, MII and S/4HANA) combined with hands-on understanding of shop-floor processes. This dual expertise ensures solutions that are both technically robust and operationally relevant.

An operations-driven, collaborative approach

We work closely with production, maintenance, quality, logistics and IT teams to co-design processes, streamline workflows and accelerate user adoption. Our proximity to the field ensures that solutions fit real operational constraints, not theoretical models.

Experience delivering complex industrial programs

We support manufacturers on S/4HANA migrations, multi-site rollouts, supply chain redesigns, and the integration of industrial systems such as MES, LIMS or automation platforms. Our experience allows us to secure governance, planning and change management even in highly constrained environments.

Trusted consultants with a strong delivery culture

Manufacturing clients value our rigor, commitment and ability to deliver high-impact industrial projects. We focus on reliability, transparency and tangible results, qualities essential to supporting continuous improvement and long-term competitiveness.

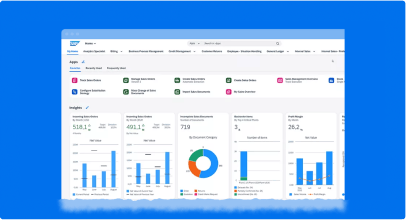

SAP solutions for the manufacturing industry

SAP S/4HANA

Unifies production, maintenance, procurement, quality and logistics on a single real-time platform, ensuring consistent processes and reliable data across the plant.

SAP EWM

Optimizes warehouse operations (receiving, storage, picking and shipping) while strengthening traceability and inventory accuracy.

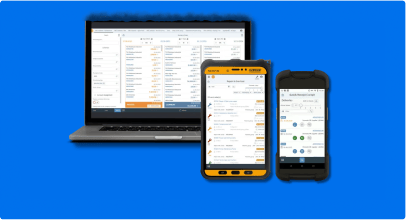

HRC Software

Ready-to-use SAP mobile applications for logistics, maintenance and procurement, designed for industrial environments and built to support frontline users, online and offline.

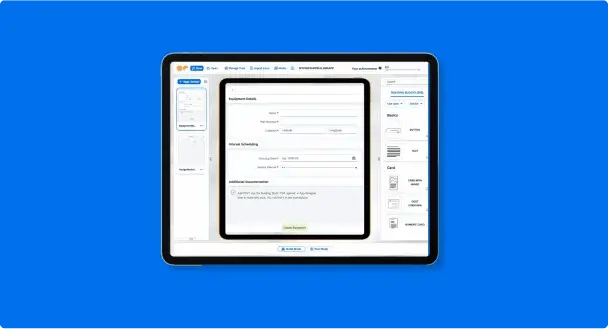

Neptune Software

A low-code platform for rapidly developing tailored, ergonomic SAP applications that fit your shop-floor and business needs.

SAP PM

Plans and orchestrates preventive and corrective maintenance to improve equipment reliability, reduce downtime and secure operational continuity.

SAP QM

Manages quality inspections, non-conformities and supplier or production-related quality processes within a unified SAP environment.

SAP MII

Connects shop-floor systems with SAP ERP, providing real-time visibility, reliable data collection and digital workflows to support Industry 4.0 operations.

Optimize your manufacturing operations with our SAP experts

- Real-time performance

- Integrated processes