Chemicals: modernize your systems and ensure compliance

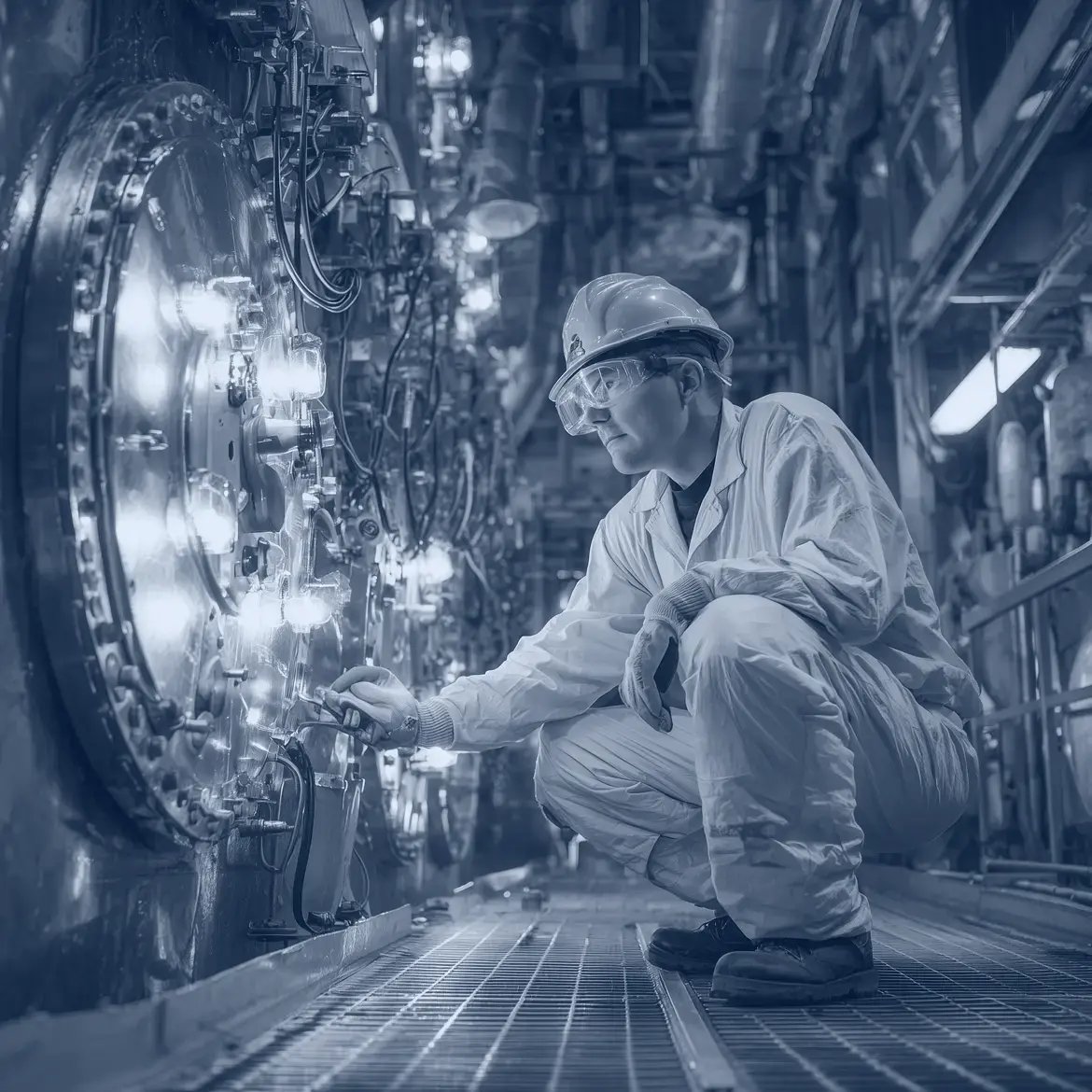

Chemical manufacturing operates under intense regulatory pressure, environmental expectations and rapid technology shifts. With complex processes, critical raw materials and strict traceability requirements, the sector demands both operational excellence and uncompromising compliance.

- End-to-end traceability

- Regulatory compliance

Key challenges in the chemical industry

Modernizing OT/IT infrastructures

Securing data and ensuring smooth interoperability between ERP, LIMS, CMMS and production systems is now essential. Chemical manufacturers must modernize their ...

Digitalizing shop-floor operations

Improving quality, cost control and traceability through sensors, mobile apps and real-time supervision.

Shop-floor digitalization - via automation, connecte...

Meeting environmental and safety requirements

Decarbonization, risk reduction and hazardous-substance management.

The chemical sector faces increasingly strict environme...

Managing resources and stocks safely

Optimizing inventory and ensuring compliance, especially on Seveso-classified sites.

Stock management in chemical plants - particularly high-risk sites ...

Modernizing OT/IT infrastructures

Securing data and ensuring smooth interoperability between ERP, LIMS, CMMS and production systems is now essential. Chemical manufacturers must modernize their OT/IT foundations to guarantee full traceability, regulatory compliance and reliable data flows across plants and enterprise systems.

Digitalizing shop-floor operations

Improving quality, cost control and traceability through sensors, mobile apps and real-time supervision.

Shop-floor digitalization - via automation, connected equipment, mobility and monitoring tools - enables tighter quality control, better cost performance and stronger end-to-end traceability. It has become a strategic lever for competitiveness in an environment where margins are under pressure.

Meeting environmental and safety requirements

Decarbonization, risk reduction and hazardous-substance management.

The chemical sector faces increasingly strict environmental regulations: emission reduction, environmental risk management, and material traceability. Decarbonization and environmental safety are now critical to maintaining operating licenses and meeting stakeholder expectations.

Managing resources and stocks safely

Optimizing inventory and ensuring compliance, especially on Seveso-classified sites.

Stock management in chemical plants - particularly high-risk sites - requires rigorous control. Companies must optimize space and material usage, ensure equipment compliance and rely on accurate tracking systems to anticipate risks and secure audits.

Our expertise in the chemical industry

We help chemical manufacturers deploy SAP solutions that are robust, connected and fully compliant with regulatory constraints. Our teams combine deep industry knowledge with strong SAP expertise to deliver projects that are realistic, secure and built for long-term performance.

Deep understanding of chemical-industry operations

We work with global groups and mid-sized chemical companies, giving us a clear view of regulatory requirements, batch and lot traceability constraints, EHS expectations and the operational realities of highly controlled environments.

SAP expertise shaped by real manufacturing needs

Our consultants bring hands-on experience across SAP PM, QM, MII/ME, MM, SD and integrated mobility (Neptune Software, HRC Software).

This allows us to design end-to-end architectures that connect shop-floor systems, quality processes, plant maintenance and logistics in a consistent and compliant way.

Operationally driven, built with your teams

We co-design solutions directly with production, maintenance, quality, supply chain and IT teams. This ensures that every process improvement is practical, adoptable, and aligned with the realities of chemical manufacturing.

A focus on securing and industrializing your projects

We support complex transformation contexts: process redesign, carve-outs, compliance projects (post-Lubrizol expectations, Seveso requirements), system consolidation and SAP S/4HANA migrations.

Our approach combines regulatory rigor with industrial performance.

A committed, flexible team built for long-term partnerships

Whether you need targeted expertise or multi-year program support, our teams deliver with reliability, proximity and a strong execution mindset. We adapt our engagement model to your constraints and stay focused on measurable results.

SAP solutions for the chemical industry

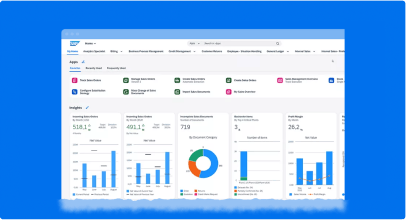

SAP S/4HANA

Centralizes production, quality, maintenance and procurement on a single platform, ensuring full traceability and end-to-end operational control.

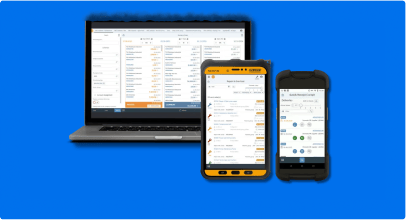

HRC Software

Ready-to-use SAP mobile applications (warehouse, maintenance, procurement), designed for industrial environments, including offline mode and full auditability.

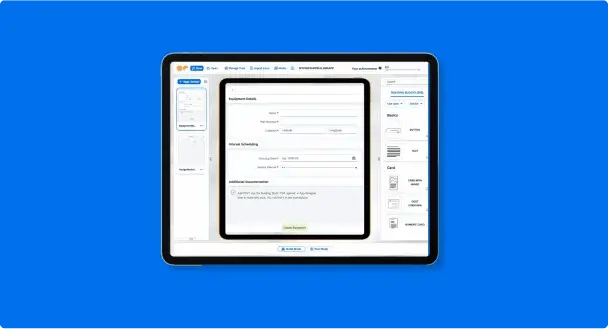

Neptune Software

Rapid development of SAP-centric business applications (inspections, audits, logistics), fully customizable and offline-capable for field operations.

SAP PM

Plans and executes preventive and corrective maintenance, securing critical assets and ensuring compliance on Seveso-classified sites.

SAP QM

Manages inspection plans, captures quality results and oversees non-conformities, aligned with stringent regulatory expectations.

SAP MII

Connects the shop floor with the ERP in real time, providing reliable production data for performance monitoring and decision-making.

SAP EHS

Strengthen safety and compliance for your chemical operations with SAP

- Regulatory compliance

- Secure sites & controlled flows