SAP PM: reliable, structured industrial maintenance

SAP PM gives you the tools to structure and digitalize equipment maintenance - from planning and scheduling to work execution and cost control - so you can improve asset reliability and overall operational performance.

- Preventive, corrective and breakdown maintenance

- Better cost control

- Long-term asset performance

What SAP PM brings to your maintenance operations

Complete asset and equipment management

SAP PM gives you a structured technical database (equipment, functional locations, task lists and bills of material) ensuring consistent information and a clear, reliable view of each asset’s condition and history.

Smarter preventive maintenance planning

Build time-based, usage-based or condition-based maintenance plans. Anticipate failures, reduce unplanned work and improve availability with rounds, measurement readings and automatic triggers.

End-to-end work order execution

From issue reporting to technical and financial completion, SAP PM manages the full maintenance cycle. Work orders are fully tracked, resources scheduled, and costs monitored, with mobile capture of interventions, time and spare parts.

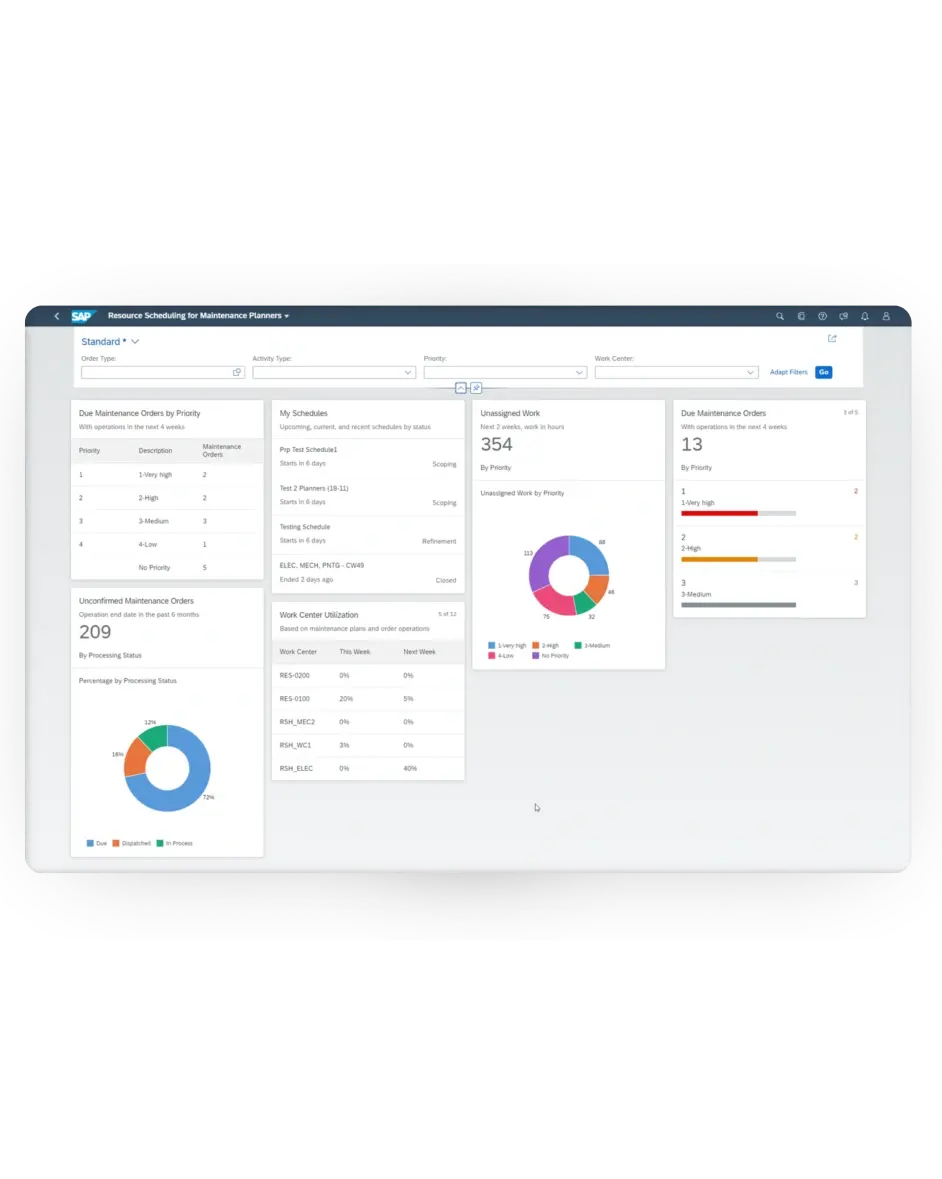

Performance monitoring and analytics

Gain full visibility into key KPIs such as availability, MTBF, MTTR, maintenance costs, backlog and plan adherence. Turn your data into actionable insights for continuous improvement.

Native SAP integration for connected maintenance

Fully integrated with SAP MM, PP and FI-CO, SAP PM strengthens collaboration between maintenance, production and finance. Real-time data enables smoother planning, automated spare-parts replenishment and accurate cost control.

Connected, high-performance maintenance with SAP PM

SAP PM centralizes your entire maintenance process, from notifications to planning, execution and performance analysis. All data flows through SAP, ensuring smooth coordination between maintenance, production and finance.

With our expert consultants, you deploy effective preventive and corrective maintenance, fully connected to production and aligned with your reliability, safety and cost-control goals.

- Centralized, traceable maintenance connected to production

- Optimized planning and real-time work execution

- Reliable budgeting and built-in performance insights

Frequently asked questions about SAP PM

Find answers to the most common questions about SAP PM: supported systems, relation to SAP EAM, production integration and maintenance KPIs.

Is SAP PM available on both SAP ECC6 and SAP S/4HANA?

Yes. SAP PM is available on ECC6 and S/4HANA.

The S/4HANA version offers a modern Fiori interface, richer integration with logistics, planning and finance, extended mobile capabilities and a significantly improved technician experience.

What’s the difference between SAP PM and SAP EAM (Enterprise Asset Management)?

SAP PM is the SAP module dedicated to planning and executing maintenance activities on equipment and machinery.

SAP EAM includes PM but goes further, offering a comprehensive, lifecycle-wide approach to asset management, from acquisition to decommissioning. It also brings advanced mobility, predictive analytics and IoT connectivity.

How does SAP PM integrate with production?

SAP PM connects with SAP PP (Production Planning) to synchronize maintenance work orders with planned downtime, minimizing production impact. Maintenance tasks are scheduled based on shop-floor capacity for smoother coordination.

Which KPIs can I monitor in SAP PM?

SAP PM provides dashboards for equipment availability, MTBF, MTTR, maintenance costs and work order backlog — giving you a clear view of performance and improvement opportunities.

Strengthen your maintenance operations with SAP PM

- Planned maintenance

- Controlled costs

- Reliable asset availability

- Integrated processes